Mumbai Refinery (BPCL - MR)

The Bharat Petroleum Mumbai Refinery (BPCL - MR) is one of the most versatile refineries in India and excels in all aspects like quality, technology, energy, human relations, safety, environmental friendliness and operating cost. .

With successful de-bottlenecking and implementation of various major projects, Mumbai Refinery has a capacity to process 12 MMT of crude oil per annum. Mumbai Refinery has processed 93 different types of crude in five decades of its operations, making it one of the most flexible refineries in the country. Mumbai Refinery uses the latest microprocessor based Digital Distributed Control System (DDCS) and has been accredited with ISO 9001 (Quality Management System), ISO 14001 (Environment Management System) and OHSAS (Occupational Health and Safety Management System). Quality Assurance Laboratory has been accredited with a certification from, National Accreditation Board for Testing and Calibration Laboratories (NABL), an autonomous body under the aegis of Department of Science & Technology, Government of India, and is registered under the Societies Act 1860. Mumbai Refinery was one of the first refineries to have got accredited with ISO 50001 (Energy Management System) in the year 2014.

Mumbai Refinery has implemented a state of the art on-line monitoring tool, covering entire functions of the refinery, for disseminating information and decision making. Mumbai refinery stands tall among the peers for adhering to all quality and safety standards and also consistently meeting MOU targets set by MOP&NG.

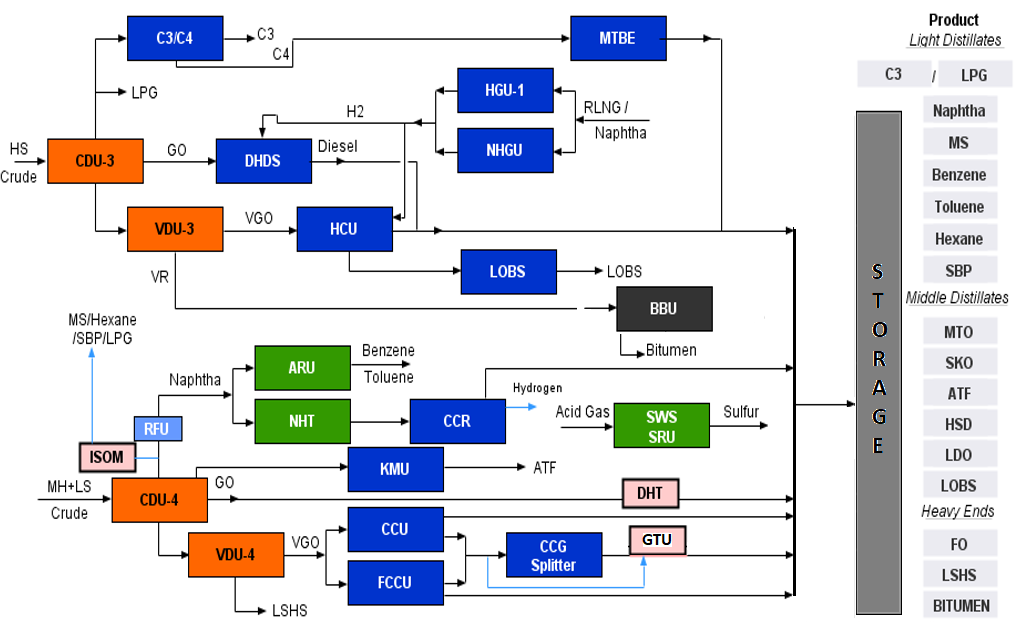

Refinery Configuration

Mumbai refinery was commissioned in 1955 with a crude oil processing capacity of 2.2 MMTPA. The refining capacity has been augmented to the present level of 12 MMT through progressive revamps, the addition of various process units and the incorporation of advanced refining technologies.

Mumbai refinery processes various types of crudes which include Bombay High, East African, Petronas, Kuwait, Arab mix, Arab medium, Basrah, Arab extra light, Murban, Umm Shaif, Western Texas Intermediate, Bantulu, Kiduong etc. The main products are LPG, Naphtha, MS, Benzene, Toluene, Hexane, SBP, MTO, Kerosene, Jet Fuel, Diesel, Light Diesel Oil, Lubes, Fuel Oil, LSHS and Bitumen.

Commissioned Diesel Hydrotreating Unit (DHT), Naphtha Isomerization (ISOM) & Gasoline Treatment Unit (GTU) to meet the government mandate of producing 100% BS-VI fuels.

The process flow diagram of Mumbai Refinery is given below:

Corporate R&D Centre (CRDC)

In today’s world, innovation is the key element for sustainable growth in a technology intensive energy Industry, without which our future would be at risk. To keep pace with the changing market demand, the Research and Development Centers of BPCL are proactively engaged in development of innovative products / process technologies and cleaner fuels / fuel additives to reduce environmental footprints while improving the Company’s profitability. In line with this prelude, the Corporate R&D Centre at Greater Noida, Uttar Pradesh and Product & Application Development Centre at Sewree, Mumbai are continuously striving for value creation through research activities The Product and Application development R&D Centre has contributed significantly to the business volume and profitability through development of new grades and alternate formulations of Lube oil. This has helped in increasing our lube oil product portfolio and reducing our input cost. The CRDC set up at NOIDA near Delhi has state-of-the-art facilities and is backed with a vision to develop high value products, services, processes & technologies to create innovative R&D solutions to earn customer’s delight.